Enhance market confidence with verified leather grading

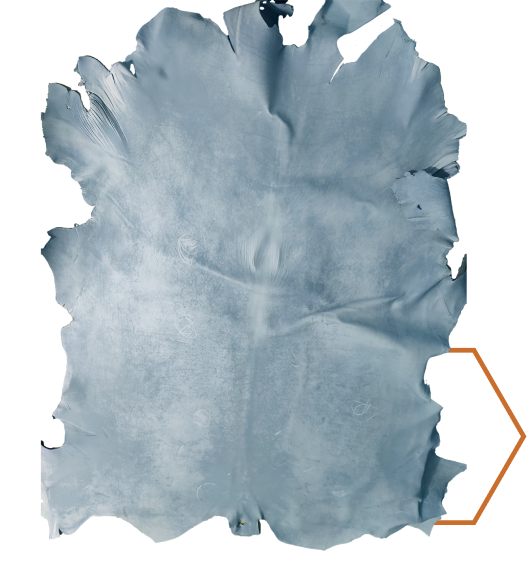

Our AI-powered leather grading system is transforming production—from wet-blue and wet-white to finished leather, offering unmatched accuracy, consistency and efficiency that scales with your needs.

Optimize your leather selection

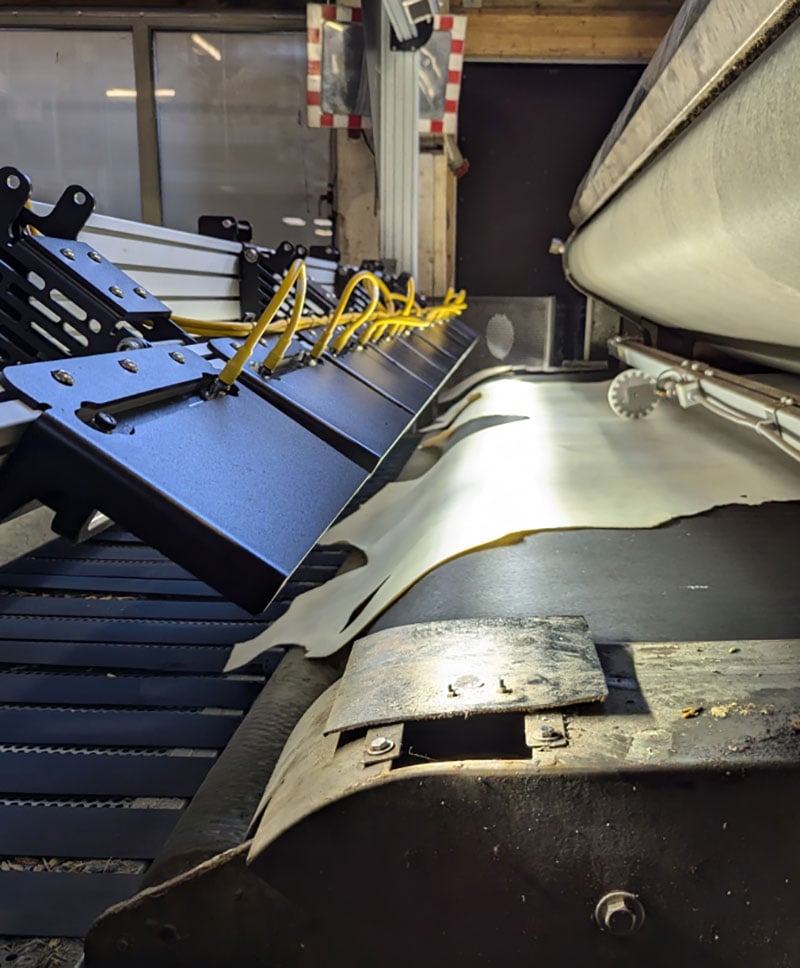

Mindhive BlueSelect™, our automated grading system is fit for demanding manufacturing environments. It seamlessly integrates behind existing sammying machines, operating at full line speed—up to 360 hides per hour, and potentially faster. Powered by our proprietary neural network and machine vision, our grading software delivers precise inspection and classification within 4 seconds, speeding up decision-making and increasing accuracy across high volumes from 91%.

Our system can map percentages of detected defects across batches, average areas, cuttable areas, and specific defect classes, such as brands—the possibilities are virtually limitless. The hide grade is either displayed on an industrial screen for manual sorting or integrated into downstream automation systems such as auto stackers.

Plus, with our detailed, verified grade reports attached to each shipment, you can confidently assure that every pallet meets your buyer’s exact standards.

Industry standard or custom ‘panelized grading’ rules

‘Smart Skirts’ maximize realistic usable area

Pablo Medina, Continuous Improvement Manager at Tasman

Watch the case study

Advanced leather grading streamlines your production

01.

High-resolution imaging

Every hide is scanned in high resolution, capturing every detail necessary for accurate defect detection—as small as a hair follicle (.2mm).

02.

Hide inspection

Our AI-driven software analyzes each image, identifying quality areas and 25+ defect classes with precision, and generating unique defect maps.

03.

Rule-based grading

The software then applies customer-specific rules to grade the leather. Each hide is graded consistently and accurately - within 4 seconds.

04.

Detailed reporting

For every hide, a comprehensive grading report is produced, including: hide image, defect map, selected grade, batch number and pallet data.

05.

Centralized dashboard

Easily access production data and insights - at site and group level - to optimize yield, benchmark efficiency, understand sourcing quality, forecast and plan.

06.

ERP integration

Your ERP system is updated with leather grading data to enhance workflow efficiency and data accessibility across your production chain.

Watch Mindhive BlueSelect™ in action

Detect 30+ defect classes on wet-blue hides

-

Bacterial damage

-

Brand

-

Chrome stain

-

Delayed cure

-

Flay

-

Growth

- Hair / Stubble

- Healed scar

- Light bite

- Neck Hump

- Open scratch

- Vein

Maximized

quality

Optimized

shipping

Operational efficiency

Reduced discrepancies

Designed for demanding tannery environments

We designed Mindhive Grading to thrive in the demanding tannery environment, integrating seamlessly with existing infrastructure and enduring harsh conditions. Every component, from the Neural Network for defect detection to the hardware capturing images, was built for this purpose. Transitioning from lab proof of concept to a scalable, deployable system required meticulous engineering.

Constructed from stainless steel, Mindhive BlueSelect™ integrates smoothly with existing wringing processes, designed to fit conveyors and outfeeds. Our imaging hardware is highly tolerant of variable conditions, processing images in real-time on-site. Our industrial-grade interactive touchscreens display a detailed defect map, usable/cuttable hide area and grade of the hide, and can communicate to PLCs and auto stackers.

Deployments typically take only a few days, with minimal downtime, allowing us to implement in busy tanneries without disrupting production.

Mindhive Grading is not just tested—it’s trusted by industry leaders who demand the best.